Chemical Properties:

Package: Bottle, 25kg/Barrel, or according to customer's requirement. Storage Condition: Store in sealed containers at cool and dry place; Protect from light and moisture.Manufacturer Supply Crosslinker Series, Commercial Production Chemical Name: Trimethylolpropane tris(2-methyl-1-aziridinepropionate) CAS: 64265-57-2| Item | Specifications |

| Appearance | Colorless to Pale Yellow Transparent Liquid |

| Solid Content | >99.0% |

| Viscosity (25℃) | 150 ~ 250 cp |

| Methyl Aziridine Group Content | 6.16 mol/kg |

| Density (20℃) | 1.08 g/ml |

| Freezing Point | -15℃ |

| Boiling Point Range | Much More Than 200℃ (Polymerization) |

| Solubility | Completely Dissolved in Water, Alcohol, Ketone, Ester and Other Common Solvents |

| Storage | Stored in a cool, dry, sealed condition. Avoid contact with acids and oxidants; Avoid freezing or high temperature |

| Shelf Life | 12~18 Months Under the Suitable Storage Conditions |

| Test Standard | Enterprise Standard |

| Usage | Crosslinker Series |

Description:

Specifications:

Package & Storage:

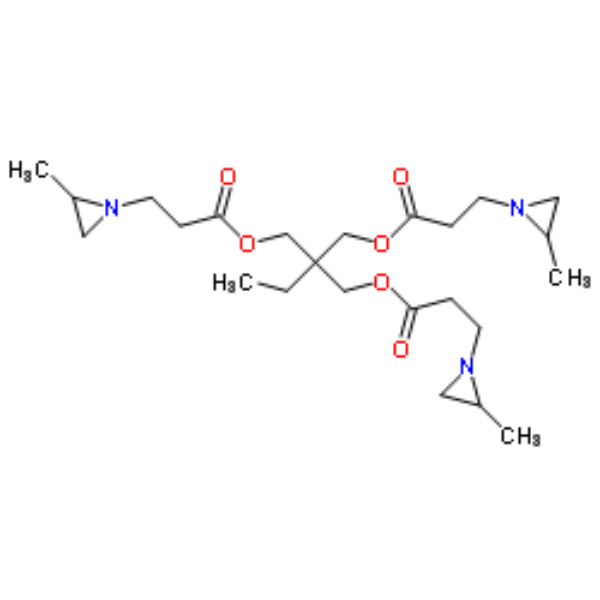

| Chemical Name | Trimethylolpropane tris(2-methyl-1-aziridinepropionate) |

| Synonyms | Polyfunctional Aziridine Crosslinker; Crosslinker CX-100; 2-(((3-(2-Methylaziridin-1-yl)propanoyl)oxy)methyl)butane-1,2-diyl bis(3-(2-methylaziridin-1-yl)propanoate) |

| CAS Number | 64265-57-2 |

| CAT Number | RF-F08 |

| Stock Status | In Stock, Production Scale Up to Tons |

| Molecular Formula | C24H41N3O6 |

| Molecular Weight | 467.6 |

| Brand | Ruifu Chemical |

Advantages:

FAQ:

Application:

Trimethylolpropane tris(2-methyl-1-aziridinepropionate) (CAS: 64265-57-2), Improve the water resistance, washing resistance, chemical resistance and high temperature resistance of leather coating; Improve the water resistance, viscosity resistance and high temperature resistance of water-based printing coating; Improve water and detergent resistance of water-based ink; Water resistance, alcohol resistance, detergent resistance, chemical resistance and abrasion resistance can be improved in waterborne parquet floor paint. Water resistance, alcohol resistance and viscosity resistance can be improved in waterborne industrial paint. In vinyl coating, the migration of plasticizer can be reduced and the stain resistance can be improved. Improve its wear resistance in water-based cement sealant; It can generally improve the adhesion of water-based system on non-porous substrate. Dosage is usually 1 to 3% of the solid content of the emulsion. The pH value of the emulsion is preferably 8 to 9.5. It should not be used in an acidic medium. This product mainly reacts with the carboxyl group in the emulsion. The customer should test according to the needs of the process.